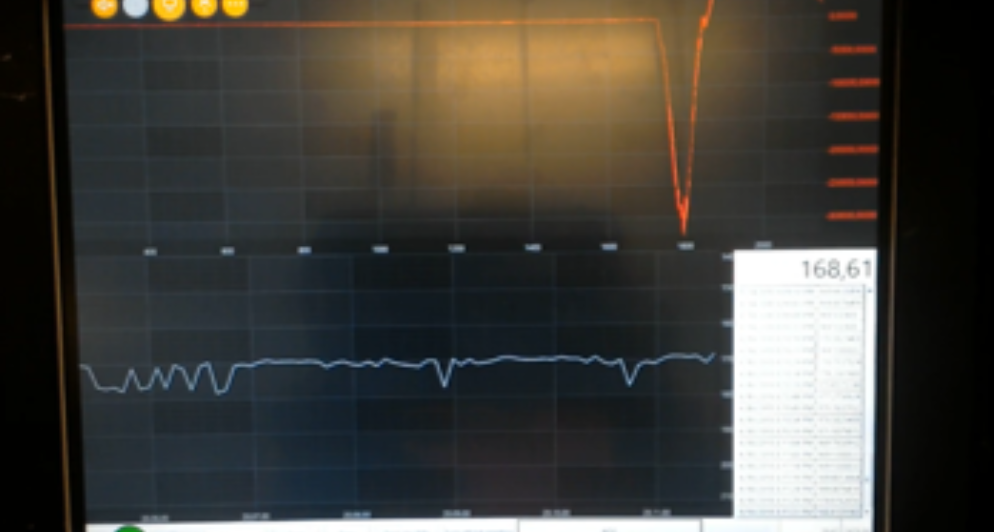

Continuous Logging of Liquid Level During Acid Stimulation

Continuous liquid level measurement

3 pelicases

Challenge

A major operator in the North Sea needed to perform perforation and acid stimulation on a newly completed well with known tubing to Annulus A communication. An alkaline liquid was injected into Annulus A surrounding the known leak depth and a gas pocket above acted as a pressure buffer. Client was concerned of alkaline liquid loss into tubing and requested a remotely operated system for real time liquid level measurements to ensure on influx of acid to Annulus A.

Solution

ScanWell designed a remotely operated portable automatic gas gun that could be programmed to perform acoustic shots at predefined intervals as well as on demand. An accompanying software was also developed that could continuously detect, analyze and report liquid level depth. The system was connected to ScanWell's Portable Surveillance Station and live data was distributed over WIFI to the rigs network allowing live monitoring by the control room operates, safety officer and land operations.

Result

ScanWell was able to continuously track changes to the liquid level during the entire operation with approximately 10cm resolution. No loss occurred and the liquid level of the alkaline solution remained stable resulting in no acid influx into Annulus A.

Client value

The client managed to put the well on production after successfully perforating and acid-stimulant reservoir section while ensuring integrity of outer casings. A straddle was subsequently installed to isolate the Tubing to Annulus A communication.